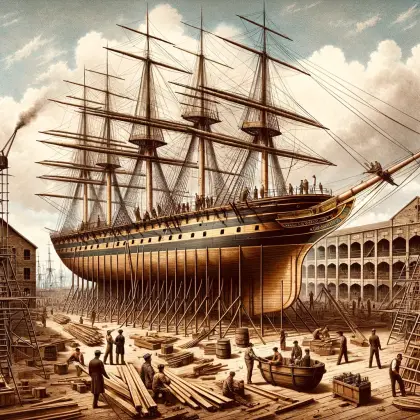

Visionary Craftsmanship: The Ambition of Cutty Sark

Amidst the fierce competition of the tea trade, the Cutty Sark was conceived as a masterpiece of maritime engineering. The ambition was not just to build a ship, but to construct the fastest vessel on the seas, a testament to the daring and determination of the age. The design was revolutionary, combining sleek lines with robust construction, aiming to slash delivery times and capture the lucrative tea market.

Challenges of Construction: Overcoming the Odds

The creation of the Cutty Sark was fraught with difficulties. The tight six-month deadline, coupled with a financial stipulation that would penalize delays, placed immense pressure on the shipbuilders. Additionally, the need for quality materials pushed the costs higher, straining the finances of Scott and Linton, who were operating in an industry where fortunes were as changeable as the tides.

Technical Marvels: The Cutty Sark’s Blueprint

The blueprint of the Cutty Sark was a marvel of its time. The narrow, streamlined hull was designed for speed, while the selection of sturdy American Rock Elm and the tough, weather-resistant Teak for the deck ensured longevity. The rudder, crafted from robust English Oak, was designed to withstand the tumultuous conditions of the high seas.

Cutty Sark’s Financial Voyage: The Cost of Excellence and the Weight of Deadlines

They would be paid £17- £21 a ton to build Cutty Sark’s max weight of 950 Tons. The contract meant it had to be built in 6 months there were fines if this was late £5 per day. The builders would get their money in stages. Captain George Moodie supervised the construction of Willis. He would eventually be the Cutty Sark’s Captain on completion—delays it needed strengthening. Scott and Linton went bankrupt building the ship. Only the finest materials including Teak Deck were being used, but these were not cheap. But they had accomplished the Hull.

Technical Marvels: The Cutty Sark’s Blueprint

American Rock Elm, Iron. The Rudder was English Oak. In the 1920s the keep was replaced by pitch pine. The deck was thick teak. Tween deck of yellow pine. Ropes by Gourock Ropeworks. They built a streamlined narrow-shaped Hull with a copper lining of 60% copper 40 5 Zinc Iron so that sea barnacles couldn’t stick to it which would drag it down and slow its speed.

A Legacy of Innovation: Cutty Sark’s Lasting Impact

The innovations that the Cutty Sark introduced had a profound impact on shipbuilding. Her construction set new standards for speed and efficiency, influencing the designs of future clippers. The ship’s storied past, marked by technological advancement and human ambition, cemented her legacy as an icon of the Age of Sail.

Restoration and Preservation: Cutty Sark’s Modern Journey

Today, the Cutty Sark stands as a symbol of maritime heritage, her history preserved for posterity. The efforts to restore and maintain the ship, such as the replacement of the keel in the 1920s and the ongoing preservation work, underline the importance of keeping such historical vessels as living museums, educating and inspiring future generations.